Drawing Illustrations Vectors Cracks Download Full Version 2024

Download Drawing Illustrations Vectors Cracks Full Version 2024

Drawing Illustrations Vectors Polymer-based composites have been widely used in dentistry since their introduction in the late 1950s. Recently, non-composite materials have been introduced as dental polymers.3–5 Excellent biocompatibility and superior esthetic qualities as restoratives. Drawing Illustrations Vectors moderate cost compared to ceramics and strong bonding ability to tooth structure make resin composites the preferred material in dental restorative applications. 1,6,7 Most dental composites consist of an organic matrix (polymeric phase), inorganic fillers (dispersed phase), and an interphase (coupling agent).

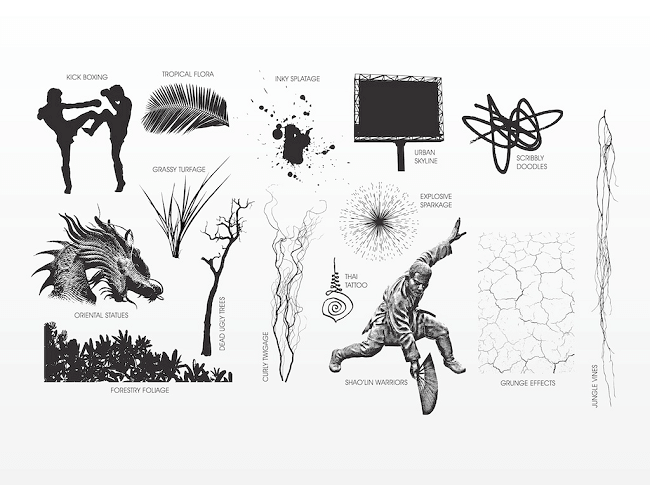

Overview of Drawing Illustration Vectors:

Polyethylene, epoxy, and matrixes are the foundation of the organic matrix. The filler is added to the polymer to improve its properties. Usually composed of different glass compositions, sizes, and size distributions.1, 2 In dentistry, resin composites typically serve as fillers for cavities, sealants for pits and fissures, cores and build-ups, inlays, veneers, crowns, dentures, interim restorations, cements for one or more tooth prosthetics, and orthodontic appliances. Periodontal sealants, screws, plates, root canal posts, and structural scaffolds.

Ceramic Particles:

fibers, paternosters, whiskers, nanotubes, and ceramic particles.12, 13 The purpose of a binding agent, such saline, is to firmly attach the filler to the matrix, enhancing the composite’s performance. The most commonly used saline solution in dental restorative composites is 3-methacryloxypropyltrimethoxysilane (e-MOS). Filler content, type, shape, size and morphology are important factors improving the desirable mechanical properties of dental composites. As well as reducing polymerization shrinkage.

Interparticle Spacing Drawing Illustrations Vectors:

7 Reduced interparticle spacing can increase barriers to dislocation motion and reduce stress localization. In order to increase the strength, toughness, and durability of dental composites, 14 different fillers have been used in this research. In addition, nanoparticles increase wear resistance and gloss retention and also improve the fatigue properties of dental composites. However, some problems remain, such as insufficient mechanical properties, water absorption, and polymerization shrinkage.

Properties of Nanocomposites:

19 However, a number of variables, such as the interphase and degree of polymer matrix conversion, have a substantial impact on the characteristics of nanocomposites. Which require a high level of silanization due to the large surface area of the nanoparticles. and poor wear resistance of large occlusal restorations during use.1, 15, and 16 dental composites fail due to surface and/or volume cracks, matrix and filler degradation, and water absorption.

Screenshots:

Key properties of Convert Drawing to Vector Illustrator:

- Increased stress concentration at the interface between filler and polymer matrix due to increased particle size.

- Poor interfacial interaction between matrix and filler. Mechanical bonding is the only bonding mechanism that holds the filler in the die due to the cooling shrinkage of the die.

- due to filler agglomeration, which acts as stress concentration sites, causing inadequate stress distribution.

- Fractures in the material result from the adjacent particles being under increased stress.

- Agglomerations limit molecular motion in the polymer during load-bearing applications, which causes deformation.

- The presence of defects at the particle-matrix interface.

Effect of Particle Size on Flexural Strength of Drawing

The addition of ceramic fillings to dental composites improves flexural strength. 29 Two similar studies also reported that the addition of HA (18, 1 µm) to the PMMA denture base reduced the flexural strength.53,54 According to Oral et al. (49, 50), the size of filler particles significantly affects the mechanical properties of particle-polymer composites.28,51 50% wt. Al2O3 (<10 µm) in dental composites increased the flexural strength by more than 100%.52 Tanimoto et al. found that the flexural strength of groups reinforced with large microparticles (>315 µm) decreased.55 Table 2 shows the effect of microparticles on the flexural strength of dental composites.

What’s new about drawing?

- As shown in Table 2, composites reinforced with high volume fractions of small microparticles have high flexural strength values.

- The improvement in flexural strength can be attributed to the increased surface area of the filler particles due to the reduced particle size, resulting in a high surface energy at the filler-matrix interface.

- A reduction in particle size at the same volume fraction leads to covalent bonding, a strong physical interaction. Increased contact area that increases adhesion at the interface between matrix and nanofiller. Additionally, smaller sizes cause more particles to share the applied stress in a specific area.

- 77 These factors lead to efficient stress transfer from the soft resin to the hard nanofiller.

- The addition of highly stiff nanoparticles, like nano-Al2O3 and nano-TiO2, causes nanocomposites to become less ductile and more rigid.

- This is because these nanoparticles can resist larger stresses.72,78,79 5. While this is happening, the following variables can be blamed for the decline in flexural strength: nanoparticles spread, stop cracks from spreading, and greatly increase flexural strength.

- Increased stress concentration at the interface between the filler and the polymer matrix due to increased particle size.29

- The presence of defects at the particle-matrix interface

- Agglomerations restrict molecular motion in the polymer in load-bearing applications, causing deformation.54

- Agglomerate

Minimum requirements for illustration vectors:

- OS: Window 10, 7, 8, 8.1, and XP.

- Graphics Card: NVIDIA GeForce 510.

- Memory: 2 GB

- CPU: Intel Core 2 Duo Q6867

- OS: Unknown Draw

- File Size: 512 MB

How to Use Drawing Illustration Vectors:

- Create the picture with basic lines and shapes.

- To keep your design structured and editable, use layers for your image.

- To give your image more color and depth, use gradients and color palettes.

- Try out various brush techniques and effects to produce your own textures and looks.

How many FPS will I get?

- Finally, both cracks will meet each other because of the extension of the microcrack.

- 43 Crack deflection and bridging often work in harmony, given that crack deflection usually leads to crack bridging.

- A schematic drawing of crack bridging is shown in Figure 4.

- Toughening ceases at this point. However, for small particle-filled composites, crack bridging is not an expected powerful factor enhancing toughness.

Conclusion of the Drawing:

The key control parameters to enhance fracture toughness are toughening mechanisms. The reason is obvious since composite strength depends on the load transfer between filler and matrix. Stiffness depends highly on particle loading. Dental composites have included a variety of nanofillers, including SiO2, ZrO2, TiO2, Al2O3, BaSO4, HA, Ag, YbF3, and nanodiamond. The results of the conducted review

![Curve Ball 3d2 Download For Windows Latest Version [Meer] OK](https://lo4d.org/wp-content/themes/ribbon-lite/images/nothumb-related.png)